Our products

-

Fittings and quick-connect couplings

-

Pneumatic push-in fittings

- 0800 - Push-in fittings in nickel plated brass

- 1800 - Push-in fittings in nickel plated brass and POM

- 1950 - Food grade push-in fittings in brass

- COMPACT - Push-in fittings in acetalic resin

- Rotary joints with push-in connections

- SENFIT - Push-in fittings in resin

- 4600 - Miniature push-in fittings

- 4200 - Food grade push-in fittings

- 5800 - Stainless steel push-in fittings

- 0900 - High-pressure push-in fittings

- 0400 - Misting push-in fittings

-

Pneumatic function fittings

- Flow control valves, "brass" version, with push-in fittings

- Flow control valves, with knurled adjusting screw, with push-in fittings

- Flow controllers, "compact" version, with push-in fittings

- Flow control valves, "compact" version, with nickel-plated brass body

- Flow control valves, "in-line" version - regulation by knurled wheel

- Pressure regulator

- Pneumatic servovalves

- Non-return valves

- Fittings with pneumatic function

- Stainless steel series pneumatic function fittings

- Non-return fittings in stainless steel

- Swivel fittings

- Standard fittings

- Distribution frames

- Air silencers

- Quick-connect fittings

- Universal double cone fittings

- DIN compression fittings

- Compression fittings for centralised lubrication

- Pneumatic quick-connect couplings

- Valves

- Claw couplings

-

Pneumatic push-in fittings

- Tubes and pipes

- Pneumatic components

- Piping system and workshop equipments

-

Pneumatic push-in fittings

- 0800 - Push-in fittings in nickel plated brass

- 1800 - Push-in fittings in nickel plated brass and POM

- 1950 - Food grade push-in fittings in brass

- COMPACT - Push-in fittings in acetalic resin

- Rotary joints with push-in connections

- SENFIT - Push-in fittings in resin

- 4600 - Miniature push-in fittings

- 4200 - Food grade push-in fittings

- 5800 - Stainless steel push-in fittings

- 0900 - High-pressure push-in fittings

- 0400 - Misting push-in fittings

Pneumatic function fittings- Flow control valves, "brass" version, with push-in fittings

- Flow control valves, with knurled adjusting screw, with push-in fittings

- Flow controllers, "compact" version, with push-in fittings

- Flow control valves, "compact" version, with nickel-plated brass body

- Flow control valves, "in-line" version - regulation by knurled wheel

- Pressure regulator

- Pneumatic servovalves

- Non-return valves

- Fittings with pneumatic function

- Stainless steel series pneumatic function fittings

- Non-return fittings in stainless steel

- Swivel fittings

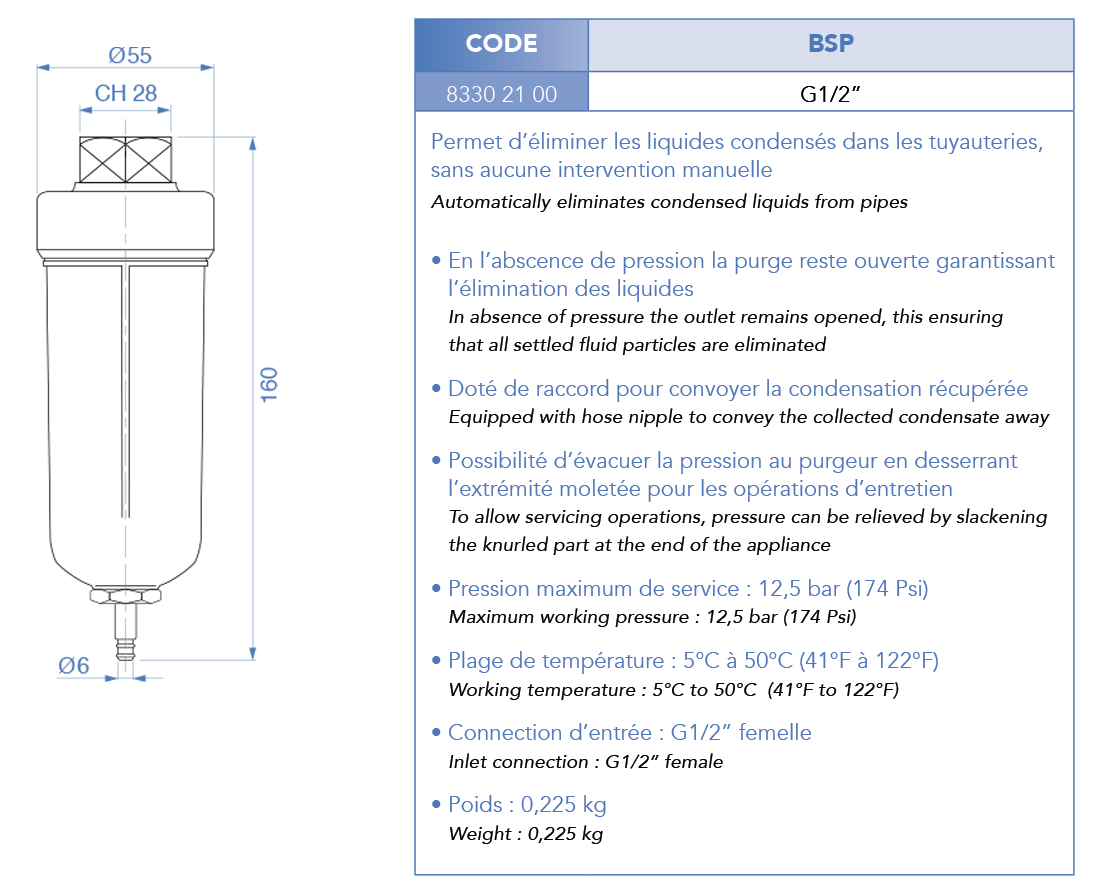

Drip leg drain

Float line purgers are an effective solution for removing condensed liquids from pipelines, particularly in compressed air networks, without requiring manual intervention. These devices are designed to ensure automatic and continuous evacuation of condensates, thereby ensuring proper operation and longevity of the installations.

Equipped with a float mechanism, these purgers remain open in the absence of pressure, allowing for constant evacuation of accumulated liquids. This feature ensures proactive maintenance, reducing the risk of equipment damage and ensuring optimal system performance.

To facilitate the management of recovered condensates, the purgers are equipped with fittings allowing for efficient conveyance of liquids to the appropriate collection point. Additionally, they feature a knurled end for releasing internal pressure during maintenance operations, ensuring safe and convenient handling.

With a maximum service pressure of 12.5 bar and a temperature range from 5°C to 50°C, these purgers are suitable for a wide range of industrial applications. Their G1/2" female input connection allows for easy integration into existing systems, while their lightweight of 0.225 kg facilitates installation and handling.

In summary, float line purgers are essential components to ensure the proper functioning of compressed air networks, offering a reliable, automated, and easy-to-maintain solution for the removal of condensed liquids.

Recently viewed products

ZAC des Romains Sud, Cran-Gevrier

74960 ANNECY - FRANCE

8:30-12 AM and 1:30-5 PM

© Airfit - All Rights Reserved

Website realized by alatak.net